Introduction: On-Site ISPM 15 Treatment Explained

For businesses managing large volumes of international shipments, logistics and efficiency are paramount. The need to treat wood packaging materials (WPM) according to ISPM 15 standards is a critical step in this process. This often raises the question: can ISPM 15 treatment services be performed on-site at a business’s own location? While the idea of on-site service is appealing for its convenience, understanding the technical and regulatory complexities is essential.

Talk to an Expert Now Get a Quote via WhatsAppThis guide explores the realities of on-site ISPM 15 treatment, detailing the stringent requirements for both Heat Treatment (HT) and Methyl Bromide (MB) fumigation. We will explain why facility-based treatments remain the industry standard for ensuring compliance, safety, and reliability, and how Al Tayseer provides trusted, certified solutions to meet your shipping needs.

Understanding ISPM 15 Compliance

ISPM 15 is an international phytosanitary measure designed to prevent the global spread of pests through wood packaging. The standard mandates that all solid wood packaging, such as pallets and crates, must be treated to eliminate pests and then marked with an official IPPC stamp. This mark certifies that the WPM meets global trade requirements, preventing costly delays, rejections, or destruction of shipments at international borders.

The Feasibility of On-Site ISPM 15 Treatment

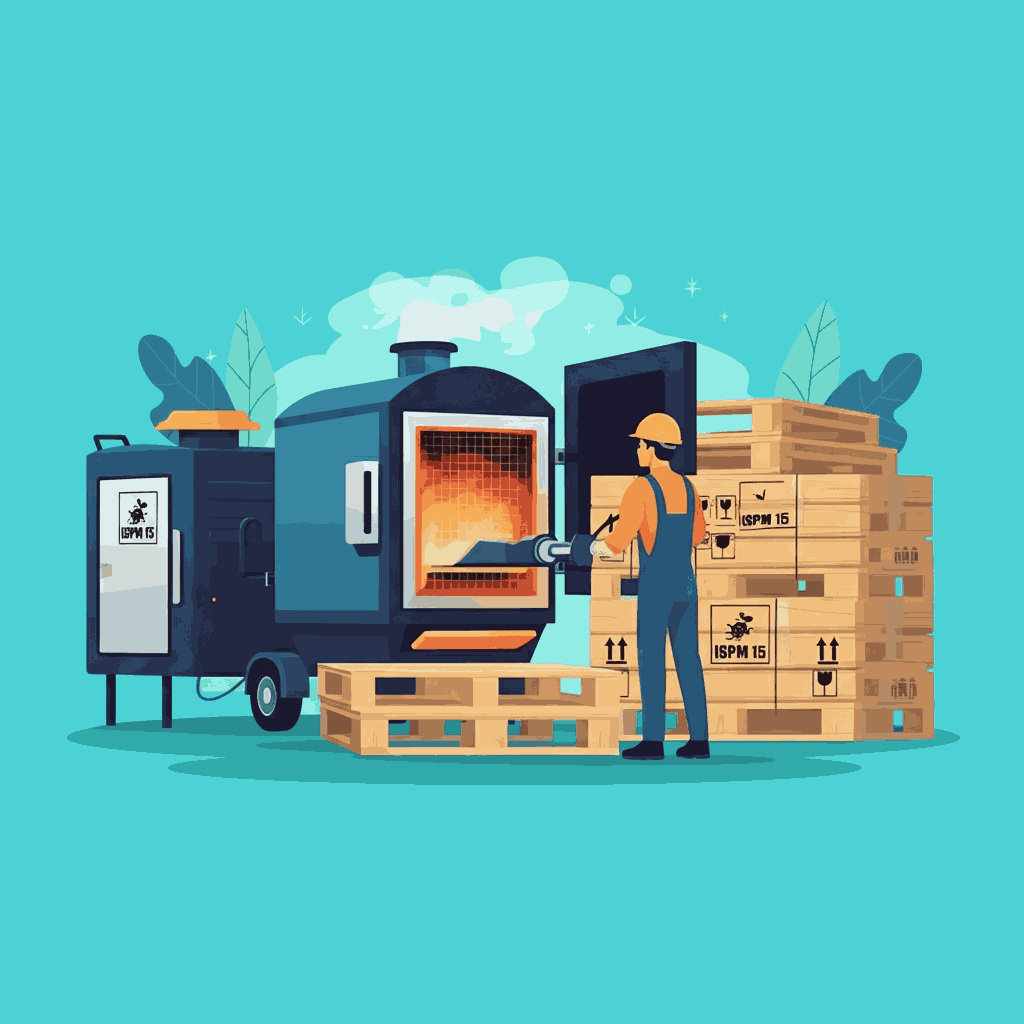

Performing ISPM 15 treatments on-site presents significant logistical and regulatory challenges. The two approved methods, Heat Treatment (HT) and Methyl Bromide (MB) Fumigation, demand highly controlled environments and specialized equipment to be effective and compliant.

On-Site Heat Treatment (HT)

Heat Treatment (HT) is the most common and environmentally preferred method. It requires heating the wood core to 56°C for a minimum of 30 continuous minutes. To achieve this on-site, a business would need to invest in a portable or permanent heat treatment chamber. These chambers must be calibrated, certified, and regularly audited by the national plant protection organization (NPPO) of the UAE. The investment in equipment, training, and ongoing compliance makes on-site HT a viable but costly option, typically reserved for very large-scale wood packaging manufacturers.

- Equipment: Requires a dedicated, certified heat chamber.

- Compliance: The process and facility must be registered and audited.

- Personnel: Staff must be trained and certified to operate the equipment and correctly apply the ISPM 15 mark.

On-Site Methyl Bromide (MB) Fumigation

Methyl Bromide (MB) fumigation involves containing the wood packaging in a sealed enclosure and introducing the gas at a specific concentration. Performing this on-site is extremely complex due to the hazardous nature of Methyl Bromide. It requires a completely sealed and secured area, extensive safety monitoring, and certified personnel to handle the toxic gas. Due to environmental regulations and the high safety risks, on-site MB fumigation is rare and highly regulated.

Why Off-Site Facility Treatment is the Standard

Given the challenges of on-site services, most businesses rely on certified, off-site treatment facilities. This approach offers clear advantages in terms of reliability, cost, and compliance.

Guaranteed Precision and Control

Approved treatment facilities operate with permanently installed, state-of-the-art equipment. These purpose-built chambers ensure that every piece of wood packaging is treated under perfectly controlled and monitored conditions, guaranteeing that the 56°C/30-minute core temperature requirement for HT is met consistently. This eliminates any guesswork and ensures full compliance.

Ensuring Regulatory Compliance

Certified facilities like Al Tayseer are registered with the UAE's NPPO and undergo regular audits. This oversight ensures that all procedures, from the treatment itself to the application of the ISPM 15 stamp, adhere to international law. By using an approved provider, you transfer the burden of regulatory compliance and can be confident that your packaging is ready for global trade.

Cost-Effectiveness and Efficiency

For most companies, outsourcing ISPM 15 treatment is far more cost-effective than investing in and maintaining on-site equipment and certifications. Approved facilities benefit from economies of scale, allowing them to offer professional services at a competitive price. This frees your business to focus on its core operations without the added complexity of running a treatment facility.

The Al Tayseer Approach: Approved Facility-Based Treatment

At Al Tayseer, we have made the strategic decision to provide ISPM 15 services exclusively at our certified and audited treatment facility in Sharjah. This focus allows us to guarantee the highest standards of quality, safety, and compliance for every client. Our state-of-the-art heat treatment chambers are precisely calibrated to meet and exceed ISPM 15 requirements.

By centralizing our operations, we ensure that every pallet, crate, or piece of dunnage is treated with unwavering accuracy. Our clients receive wood packaging that is not only pest-free but also properly stamped and fully documented for hassle-free customs clearance worldwide. This professional approach provides the assurance and reliability your business needs to compete in the global market.

Conclusion: Prioritizing Compliance and Reliability

While the concept of on-site ISPM 15 treatment offers convenience, the practical and regulatory hurdles make it an impractical solution for most businesses. The stringent requirements for equipment, certification, and safety mean that off-site, facility-based treatment remains the most reliable and cost-effective method for ensuring compliance.

Partnering with a certified provider like Al Tayseer removes the risks and complexities from your hands. By relying on our expert services and approved facility, you can be certain that your wood packaging meets all international standards, protecting your shipments from delays and securing your supply chain.

Frequently Asked Questions

- 1. Can a business get its own ISPM 15 certification to perform on-site treatments?

- Yes, it is possible for a business to become a certified treatment provider. However, it involves a significant investment in approved equipment, rigorous training, and passing regular audits by the national plant protection organization. For most companies, it is more practical to use an existing certified provider.

- 2. Is mobile heat treatment a viable option for on-site services?

- Mobile heat treatment units exist, but they still must be certified and operated by trained personnel under strict guidelines. The consistency and reliability of a fixed, permanent chamber at an approved facility are generally considered superior for guaranteeing compliance.

- 3. Why is Methyl Bromide fumigation not recommended for on-site use?

- Methyl Bromide is a highly toxic gas that is harmful to humans and the ozone layer. Its use requires extensive safety precautions, restricted access zones, and specialized handling. Due to these high risks, it is almost always performed in a dedicated, controlled fumigation facility.

- 4. Does Al Tayseer offer pickup and delivery for wood packaging that needs treatment?

- Yes, we can arrange logistics to transport your wood packaging materials to our Sharjah facility for treatment and return them to you, ready for use. This provides a convenient, end-to-end solution for our clients.

- 5. What is the turnaround time for treatment at your facility?

- Turnaround time depends on the volume of wood packaging. However, we strive to provide efficient service to minimize disruption to your supply chain. Please contact us directly for a specific timeline based on your needs.